Now all the individual engines can be removed. This is best achieved by rotating the assembly to allow a vertical lift for each block. No 4 is the hardest as the manifold prevents easy access to the bolts. It’s bad enough when reassembling but next to impossible with non existent bolt heads. There is not enough room to get a cutting torch in but I found I could just get a gas welding torch in the gap. Heating the remains of the bolt up to yellow and then turning the acetylene off allows the oxygen to act as a cutting jet and very neatly removes the head!

No 1 off

No 2

No 3

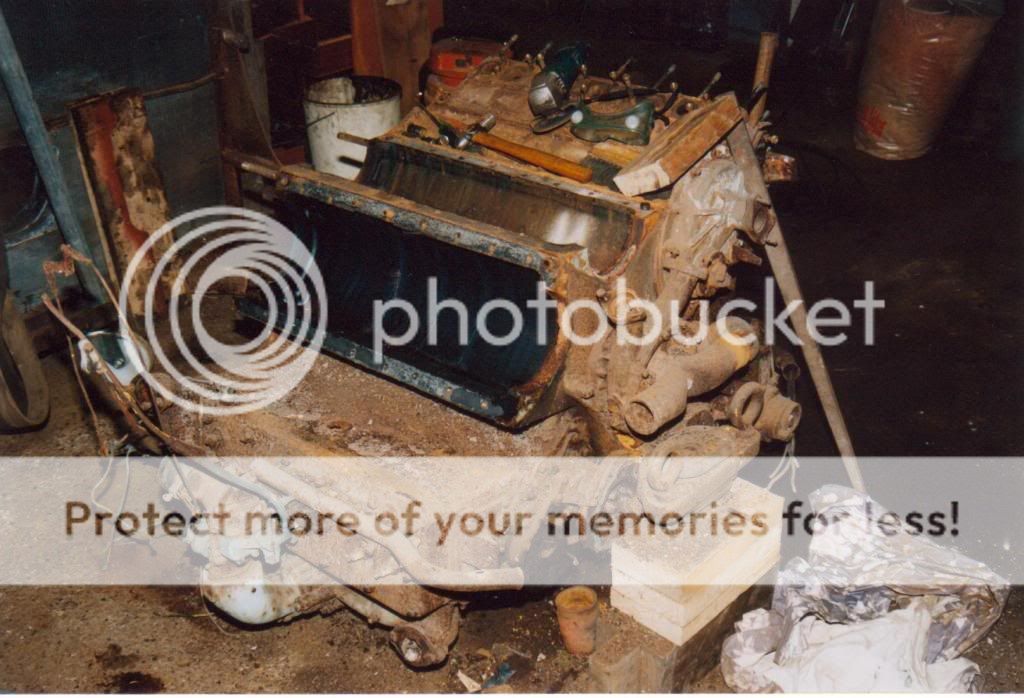

Eventually, you are left with just the centre block. It is upside down here and you can see the oil pumps, one pressure, one scavenge that are driven via bevel gears from the centre drive.

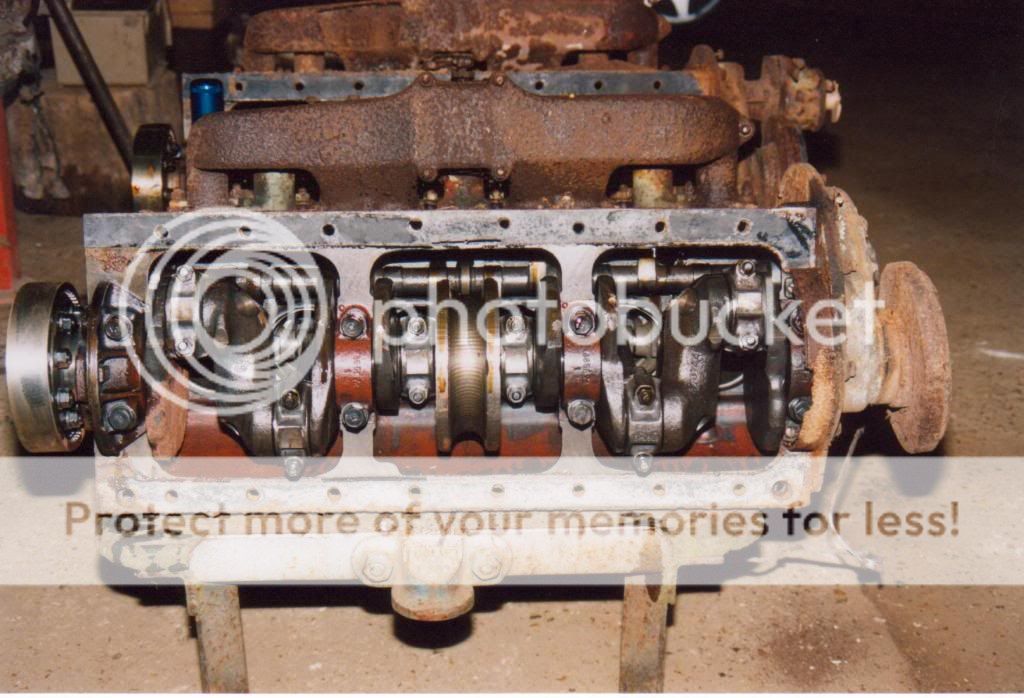

Some of the internals were in amazing condition.

In fact, on one block I was able to slip out two of the six pistons. Others required a lot of force….