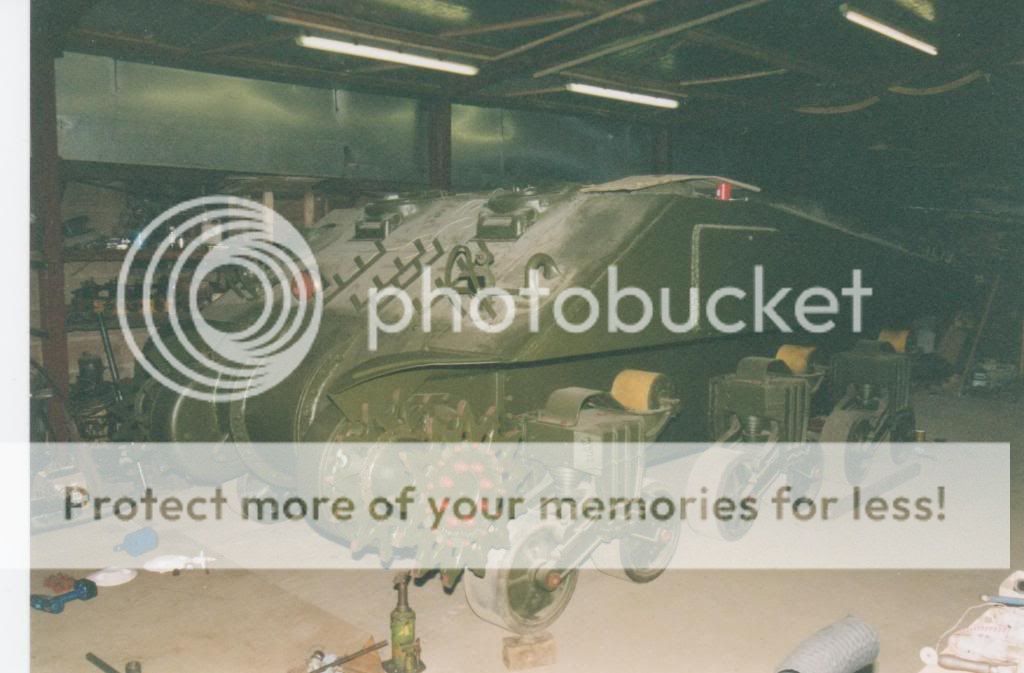

Anyway, having got as much of the interior fitted as I needed, I started on the transmission. Again a lack of pictures but essentially all I did was replace all the hub studs and renewed the shaft seals. I inspected the insides carefully and it was like new. Only half a cup of water came out when I drained all of the oil and the brakes were fine.

So just blasting and painting before fitting.

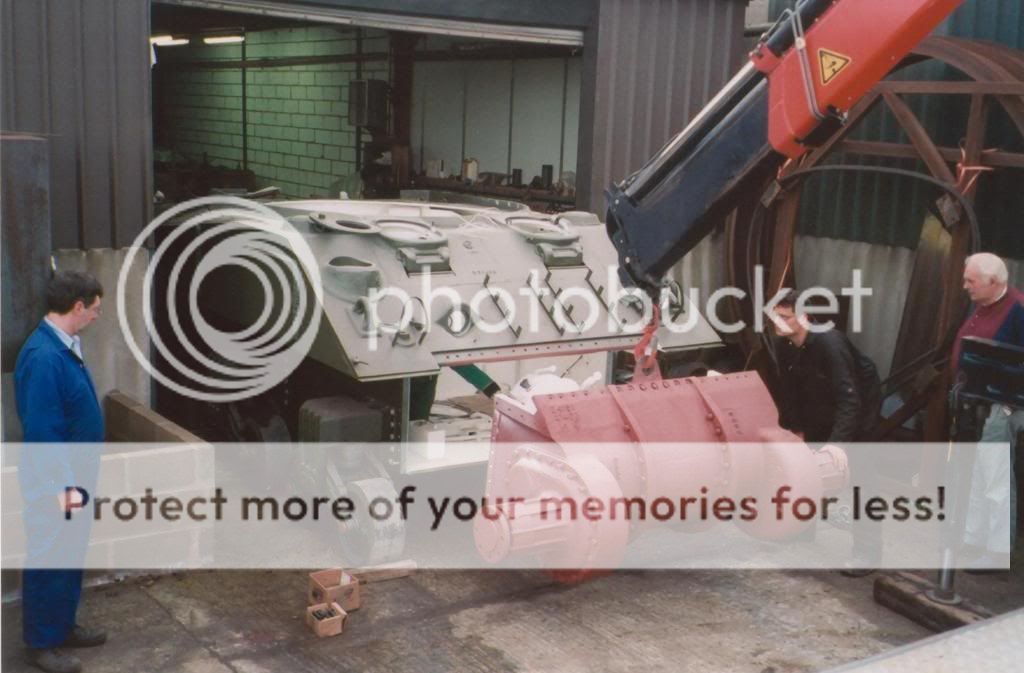

The fitting was courtesy of fellow tank owner Andy Blackford who kindly brought his HIAB truck up for the fitting. It’s not difficult but you do have to be careful if only of your fingers. The joints as they come together are like a guillotine!

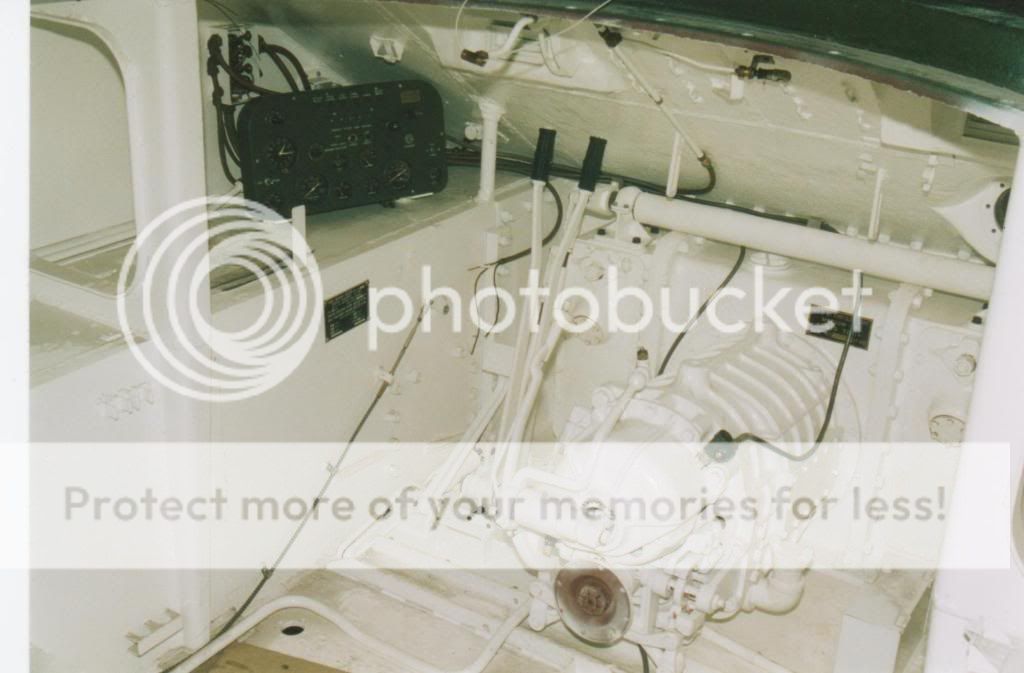

After the front is in, there is another raft of parts to fit including the drivers controls.

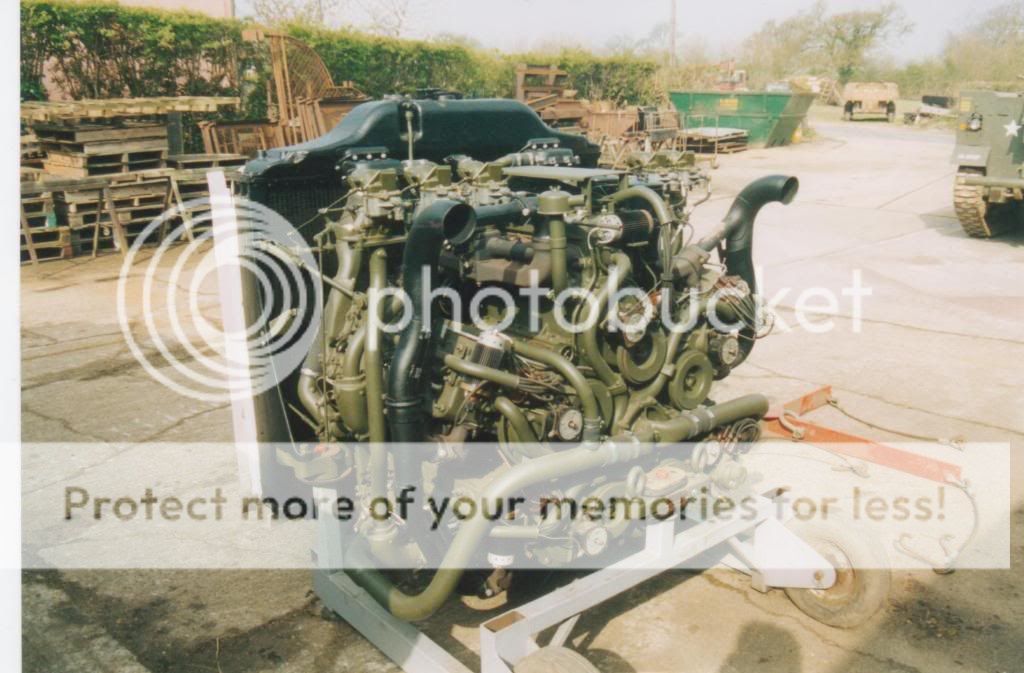

Now for the engine……

I had a little bit of concern at this point because many of the parts I had made such as the water and oil pipes were made from very poor patterns and as there is so little room in the engine bay, there was a good chance something may not fit. Only one way to find out!

Here is the engine on it’s stand ready to drop in. I have removed all of the distributor caps and tied them back in case they get smashed. They are at the extreme rear of the engine and would not stand 2 1/2 tons pushing against them.

Using another ‘favour crane’, we dropped the engine in gently only to find the oil pipe was in the way!

So it was out with the engine again while I quickly made another.

Success this time!

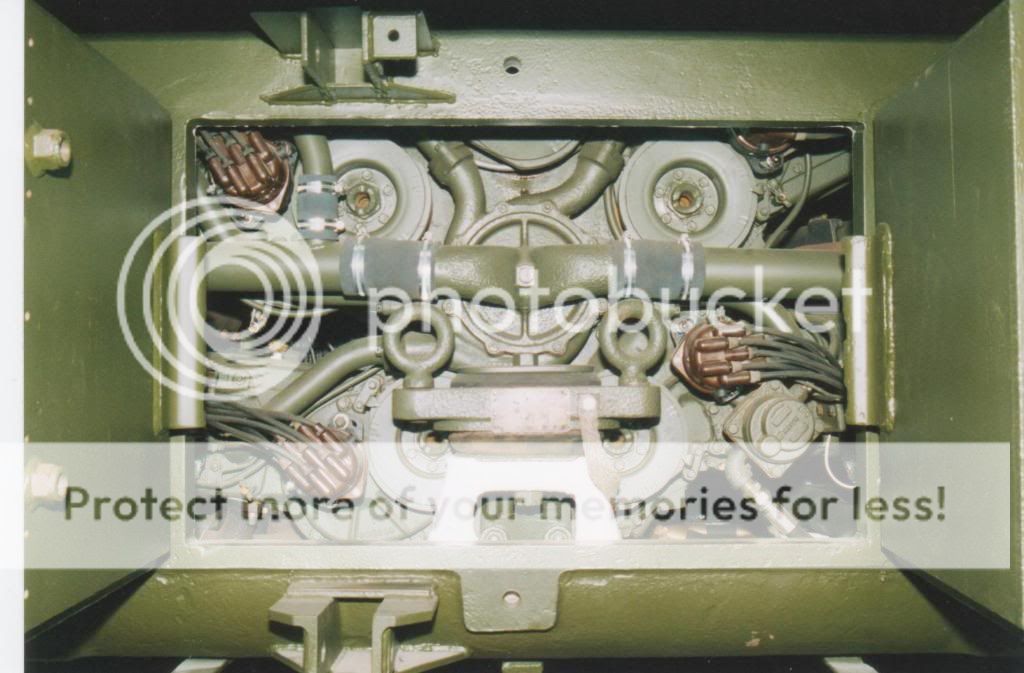

With the engine in, you can see how little room there is. The pipe connecting all the carbs to the air cleaners was another part I had to make.

A view from behind.

I overhauled the propsaft fitting new bearings throughout and had both engine and transmission oil coolers re-cored. Together with a new oil tank and working extinguishers, I was getting ready for a run.

However, I couldn’t go far yet, I still had all of the rest of the drive train to do. NOS sprocket rings from Belgium, skids, rollers and idlers all went on rapidly.